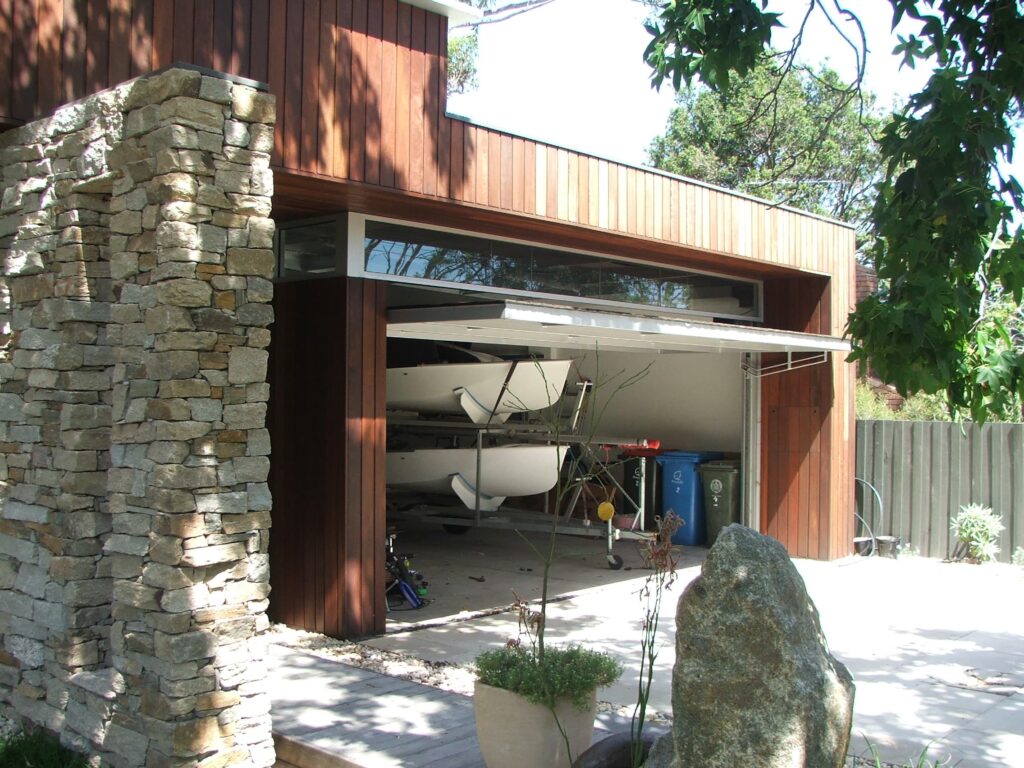

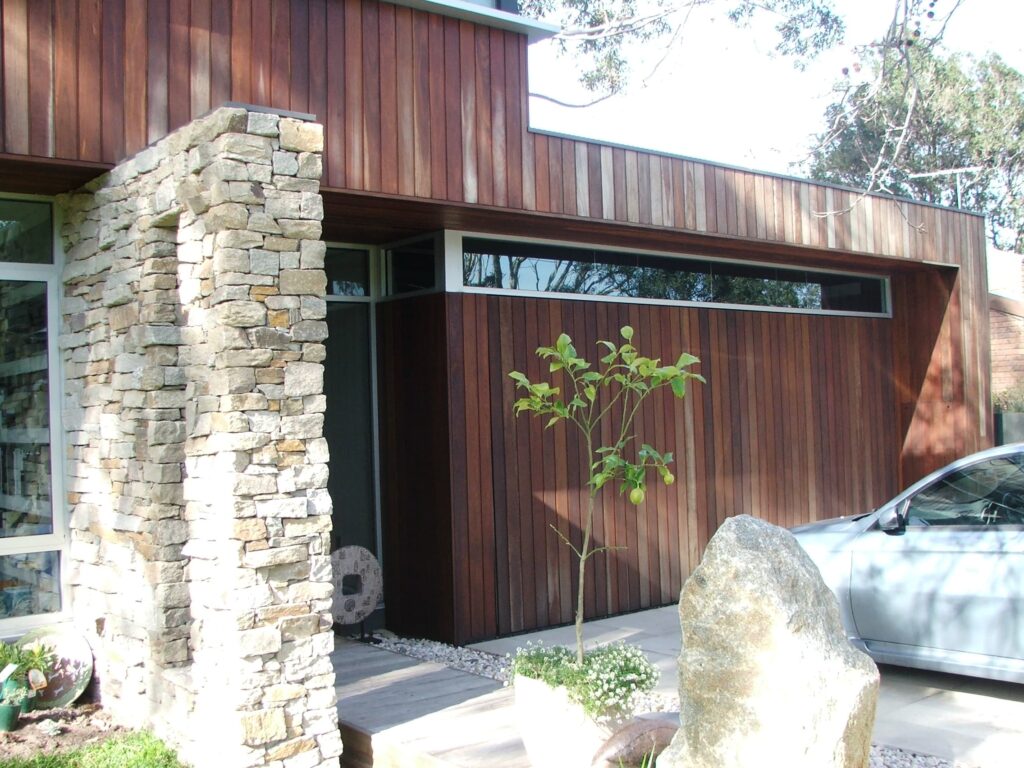

The Floataway door is a rigid panel, a tubular steel framework with cladding attached. It fits between the jambs, floor and lintel. As the door opens it rotates (about its mid height) from the vertical to the horizontal, coming to rest under the lintel at the top of the opening.

When open, the door projects half outside/half inside. Due to its external projection the Floataway is normally used where the opening is set back from the property boundary. It is commonly used for domestic garages and commercial car parks.

Being a single-leaf and counterweight balanced the Floataway door has few moving parts and is subject to uniform loading. These features result in high reliability and very long service life.